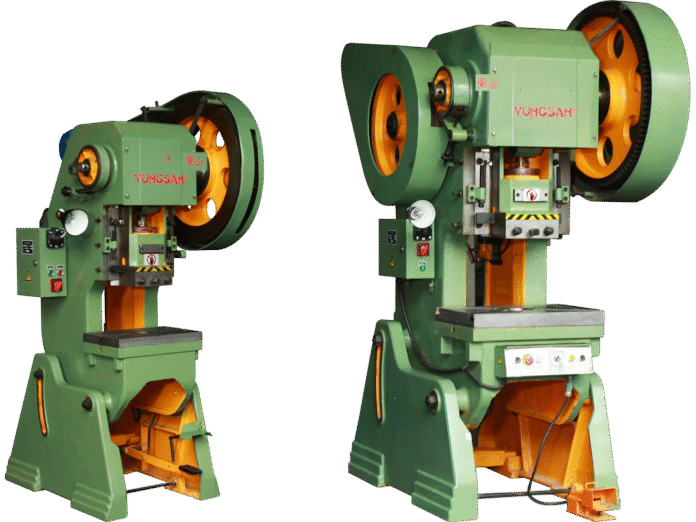

The power press industry has witnessed significant innovation in recent years, driven by the demand for higher productivity, greater precision, and enhanced safety in manufacturing processes. Power press machines are essential in industries such as automotive, electronics, construction, and appliance production, where high-volume and accurate metal forming, stamping, and punching are required. Innovation in this sector ensures that manufacturers can meet evolving industrial demands while improving operational efficiency and reducing costs.

A Power Press Manufacturer increasingly integrates advanced technologies into machine design and production processes to remain competitive. Manufacturers are adopting trends such as servo-driven presses, smart automation, energy-efficient systems, and predictive maintenance to improve performance and reduce downtime. These innovations not only enhance the functionality of the press machines themselves but also provide manufacturers with a stronger position in a highly competitive global market.

Servo-Driven Press Technology

One of the most notable trends in power press manufacturing is the adoption of servo-driven press technology. Unlike traditional mechanical or hydraulic presses, servo-driven machines use electric servo motors to control stroke speed, force application, and motion profiles with high precision. This allows manufacturers to perform complex operations, such as variable-depth stamping and progressive forming, with improved accuracy. Additionally, servo-driven presses consume less energy and produce lower noise levels, aligning with both efficiency and sustainability goals.

Automation and Robotics Integration

Automation continues to transform the power press industry. Manufacturers are integrating robotic arms, automated feeders, and conveyor systems to streamline production processes and reduce manual labor. Automation allows for higher throughput, consistent quality, and improved safety by minimizing operator interaction with moving components. Modern press lines also include real-time monitoring systems that track machine performance, enabling operators to make data-driven decisions and maintain uninterrupted production.

Smart Manufacturing and IoT

The implementation of smart manufacturing principles and IoT (Internet of Things) technology has become increasingly common among innovative power press manufacturers. Sensors embedded in machines monitor parameters such as force, vibration, temperature, and cycle speed. Data collected from connected presses can be analyzed to predict maintenance needs, optimize performance, and prevent unplanned downtime. This predictive approach improves efficiency and reduces maintenance costs, allowing manufacturers to maximize the lifespan of their equipment.

Energy Efficiency and Sustainability

Sustainability has emerged as a critical consideration in power press innovation. Manufacturers are adopting energy-efficient drives, hydraulic systems, and servo motors to reduce electricity consumption. Additionally, recycling programs for lubricants, coolants, and metal scrap are being implemented to minimize environmental impact. By focusing on energy efficiency and sustainable practices, manufacturers can reduce operational costs and support corporate responsibility initiatives, which are increasingly important in global supply chains.

Advanced Materials and Surface Engineering

Innovative power press manufacturers are also experimenting with advanced materials and surface treatments. High-strength alloys, wear-resistant coatings, and heat-treated components extend the durability and reliability of machines. Surface engineering techniques reduce friction, improve load-bearing capacity, and protect critical parts from corrosion or premature wear. These material advancements allow presses to operate at higher speeds and under heavier loads without compromising precision or lifespan.

Enhanced Safety Features

Safety remains a top priority in power press innovation. Modern machines feature integrated light curtains, interlocks, emergency stops, and operator presence sensors. Engineers design presses with ergonomic controls and protective housings to reduce the risk of accidents and improve operator comfort. Innovations in safety systems not only protect workers but also minimize production interruptions, contributing to overall efficiency.

Digital Twins and Simulation

Digital twin technology is becoming an essential tool for power press manufacturers. By creating virtual models of machines, engineers can simulate production processes, test designs, and predict performance under different operating conditions. This approach allows for optimization of machine parameters before physical production, reducing development time, improving accuracy, and preventing costly errors. Simulation also aids in designing maintenance schedules and training operators without interrupting actual production lines.

Conclusion

Innovation among power press manufacturers is transforming the industry, enhancing precision, productivity, safety, and sustainability. Trends such as servo-driven technology, automation, smart manufacturing, energy efficiency, advanced materials, and digital twins are redefining how presses are designed, produced, and operated. By embracing these technological advancements, a power press manufacturer ensures that its machines meet the evolving needs of modern industries, delivering reliable, high-performance equipment while maintaining operational efficiency and competitive advantage.